Applications

The JP3 Verax system brings unparalleled versatility and efficiency to your operations, with compatibility across a wide range of applications. This adaptability means that, regardless of the number of measurement points, the phase of measurement needed, or the specific requirements of the area, the JP3 Verax system can be tailored to meet your unique needs—streamlining processes, enhancing accuracy, and improving safety across your operations.

Each JP3 Verax system is compatible with all applications; the letter codes denote differences in number of simultaneous read points, measurement phase, and area classification:

Verax Product

Number of Read Points

Sample Phase

Area Classification

Upstream

Applications in the upstream sector include monitoring well performance, reservoir modeling, seismic data analysis, production optimization, and predictive maintenance of drilling equipment.

Fuel Gas Measurement

Field Gas BTU Measurement

Vapor Pressure Measurement

Crude Oil Boiling Point Analysis

Crude Oil Viscosity Measurement

Custody Transfer

Flare Gas Calorimetry

On/Off Truck & Rail Loading

Midstream

Applications in the midstream sector include monitoring pipeline integrity, managing inventory levels at storage facilities, optimizing transportation logistics, and ensuring compliance with safety and environmental regulations.

Fuel Gas Measurement

Vapor Pressure Measurement

Fractionation

Gas Plant Balancing

Stabilization

Crude Oil Boiling Point Analysis

Crude Oil Viscosity Measurement

Flare Gas Calorimetry

Custody Transfer

Automatic Batch Interface Detection

On/Off Truck & Rail Loading

Downstream

Applications in the downstream sector include process optimization, quality control, inventory management, and supply chain optimization.

Pipeline Interface Optimization

Crude Feedstock Valuation

Coming soon

Crude Distillation Unit (CDU) Measurement

Crude Oil Boiling Point Analysis

Crude Oil Viscosity Measurement

Gasoline Blending

Flare Gas Calorimetry

Custody Transfer

Automatic Batch Interface Detection

On/Off Truck & Rail Loading

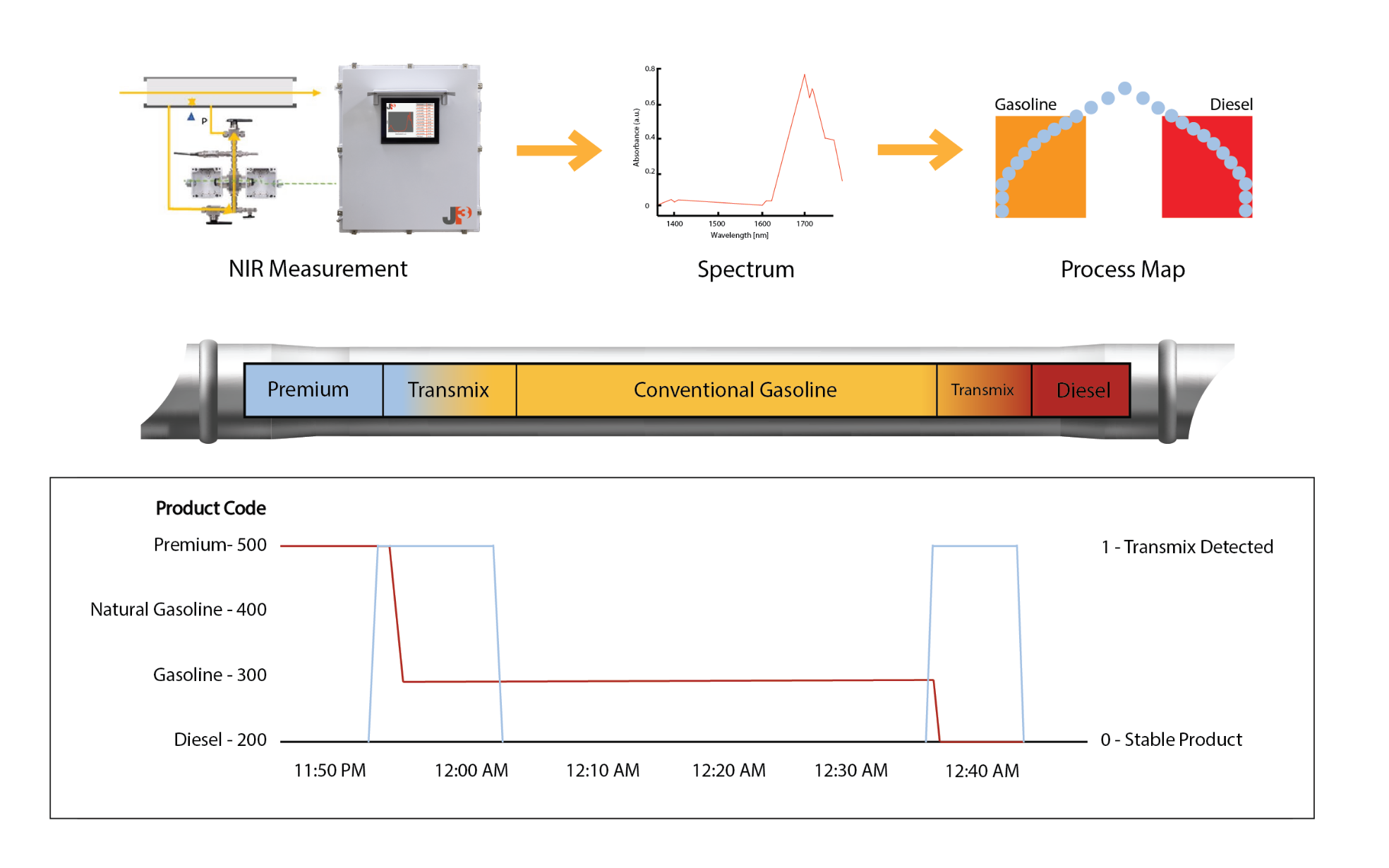

AIDA fOR VERAX:

A Machine Learning Solution for Transmix Reduction

Introducing AIDA, your groundbreaking solution in machine learning for optical signal analysis. This advanced system effortlessly identifies and analyzes product stability without needing constant calibrations, seamlessly integrating with all JP3 Verax spectrometers. Experience unparalleled precision in measuring hydrocarbon composition, Vapor Pressure, BTU, API gravity, and more. With Verax’s robust design — no moving parts, consumables, or sample conditioning — enjoy lower maintenance and longer life. Choose AIDA for reliable, efficient analysis.

Why Switch to This Powerful New Tool?

- Existing interface detection methods are either slow, or unreliable.

- Manual sampling and analysis is slow and can take multiple hours to confirm that a new batch is on-spec.

- Existing on-line methods, such as acoustic densitometers, do not provide enough information to definitively identify interface boundaries.

- Reduces waste and improves profitability

- Provides simple, actionable data